Recent Projects

Some Interesting Repair Projects completed at Tim’s Guitar Workshop

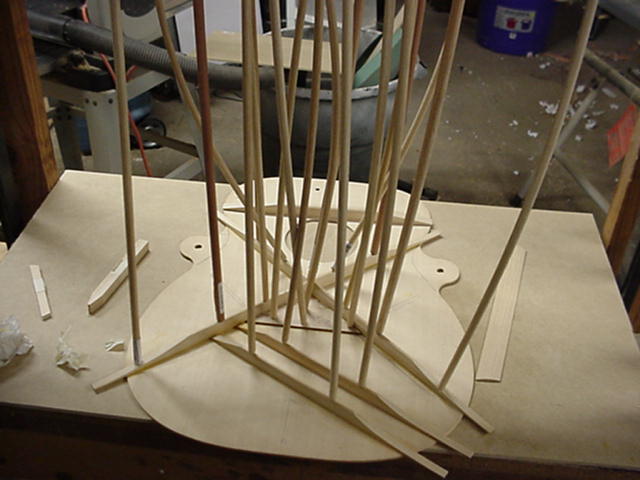

- Martin Top Replacement

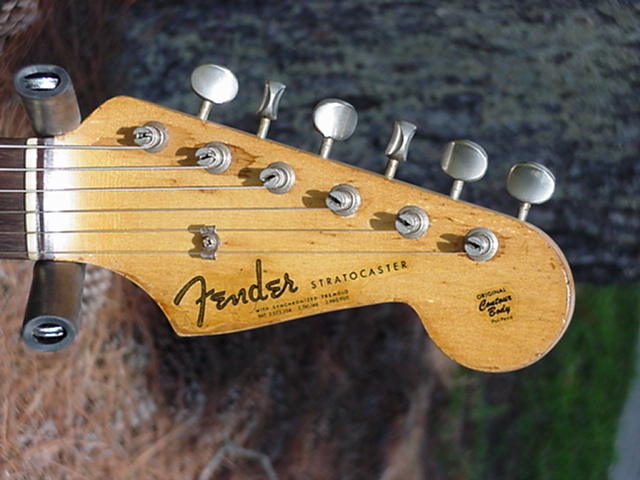

- Fender Strat

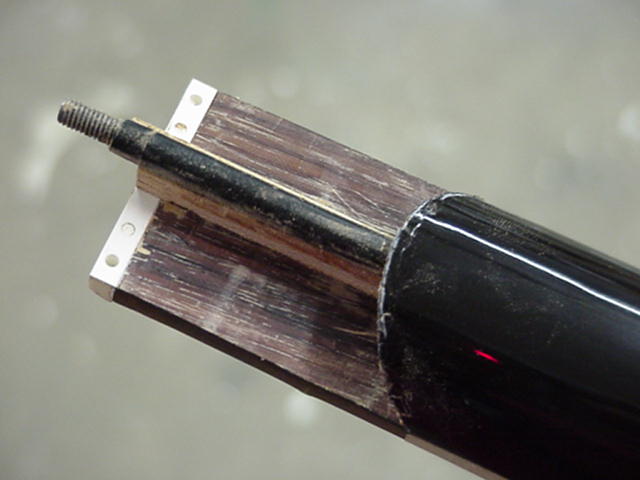

- Broken Headstock

- Classical Headstock

Another look at top being clamped into position. When we removed the old top I saved the original top binding to reuse on this new top. This extra step really is worth the effort to keep this guitar looking very vintage and original. Many shops will router off the binding and use what ever is currently available. I was lucky this time.

AFTER

This was a complicated project that was a pleasure to restore. Many thanks to Mr. Bowman for his endless patience and confidence with my shop. Some more cool things that cant be seen in the photos is the fine “Relic” type aging of the toner with very cool weather “checking/cracking” of the Nitrocellulose lacquer finish coats. With a little time and some real play wear this instrument will age gracefully like a fine bottle of wine!